As we make custom things, prospective clients intermittently ask us about how 3D printing might be used to make awards. Since we like to be detailed and authoritative in response to questions, this usually produces a long, thought-out response. To simplify the question and answer for ourselves and our clients, my sales staff has asked me to write this blog post on the subject.

Let’s first note that this is written as of late June, 2014! Technology can change! When it does, I’ll update this post – if there is no update, please assume that the general principles still hold.

3D printing is a super exciting technology. For a manufacturer of high-quality, custom, heirloom items as we are, it is one tool out of countless tools and machines that can be used to make things – including and especially human hands. I think that a lot of the potential interest for 3D printing is that people may assume that with this technology, a custom award could be made more quickly or more cost effectively. To unravel this question, we have to take a step back and consider what kind of product we are talking about making, and we have to keep in mind the materials and the finish. For the kind of awards that we make, precise control over the finish is necessary, often electroplating is necessary, and of course high quality is necessary. All of the entry-level 3D printers use relatively inexpensive plastic materials that are not suitable quality to be awards as they come out from the machines. More expensive machines can do a better job, but we’re still talking about plastic parts, and more expensive machines means more expensive products. As of now, we are still not able to make fine objects directly 3D printed in metal.

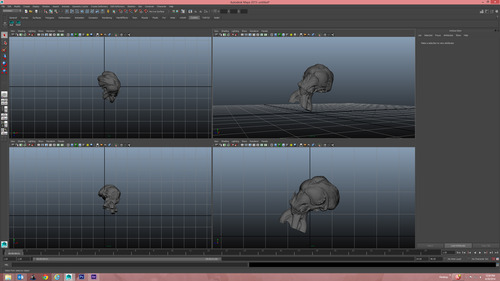

We next need to separate talking about making models and molds, from which we could then cast metal or high quality objects, and using the 3D printer itself to make the final object – which is the part that is not practical and not high quality enough, currently. When we are talking about making models and molds, then that is a possibility, but when you have extensive manufacturing capabilities at your disposal, the 3D printer is just one of many possible tools to use. Finally in that case, we are still talking about making models and molds, so that the 3D printer is not a magic bullet to get inexpensive sculpture.

The other thing that needs to be considered is the amount of time that it takes to create the 3D drawing that can be used to 3D print an object. If the item is very simple, then it may not take a long time, but it also would not take a long time to simply make it by hand or directly machine it. Depending on quantity, you do not always need models and molds for simple designs, they can be machined or fabricated – so the 3D printed model is not used in that process at all. If the item is extremely intricate, then it would take just as long – or in many cases much longer – to make the complete 3D rendering itself in the first place than to sculpt it by hand from clay. And here’s the point of the matter – we do have the option to use hands and clay, and can achieve the same result, possibly faster. Many people do not have access to factories and do not have hand sculpting capabilities, so they only have the computer software and the 3D printed model option. In that case, it comes down to the tools that you are most comfortable with. If you work with computers and you can make the model in software, and the item is going to be very complicated and we’re going to cast it, then maybe we can use that rendering to help with the model. On the other hand we could work from a variety of alternative types of models as well. And we must keep in mind that in this case we are still just talking about creating the model, which is not the most expensive part of the process. However, the model could be the most carefully controlled part of the initial process, so depending on an individual artist’s preferred tools, we might start from a computer rendering. If we are doing all of the designing and conceptualization, rather than working with an outside artist, for complicated items we will likely utilize our clay model makers as being simply faster to make and faster to make changes. Through Society Awards, our clients and artists working with them do have access to this wide range of industrial and artisan processes.

There are many scenarios where 3D printed models would be far superior to hand made clay models. An example would be a situation where you absolutely must know how the item feels in your hands. For awards, if you have an accurate design, you have estimated dimensions, you can be very confident of what that is going to look and feel like, and you aren’t going to want to make refinements by the millimeter or eighth of an inch after touching it. In that case, you are contemplating a single model and therefore making that model and changes to it will be the focus. After that, a mold is made, and then casting – assuming the object is complex enough or high volume enough to warrant casting. In the case of other objects – cell phones for example – it’s not enough to see an image of it and be informed of the dimensions. You have to feel it in your hands, and probably make very subtle changes. It would not be convenient to make a clay model of a phone, cast it, and then make a whole new clay model to refine the dimensions. It would be far easier and faster to make a rendering, 3D print it instantly, see how it feels, adjust the rendering and save different versions, print another instantly, etc. However, keep in mind that those are prototypes – not finished items suitable for presentation as a valuable honor. The finished product is still separated by the setup expenses and steps in between.

The short answer on the 3D printing situation is that we need to make valuable finished items. 3D printing can be a tool to use in the overall process to achieve that, but right now it does not produce the direct end results that are suitable to be high quality trophies as they come off the printer. We can, however, utilize 3D renderings to huge benefit in making new custom designs and we do so routinely, by combining the computer drawings with the rest of the manufacturing techniques used to make art.

PREVIOUS POST

PREVIOUS POST